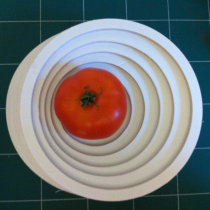

TOPOCUT is a cutting board.

Design for all people.

But at first, it was designed thinking of Parkinson’s patients.

My Role

Research, Design, UX, User testing

topo

TOPOCUT was carried out in collaboration with ABBVIE a pharmaceutical company,

which manufactures and markets drugs for the treatment of Parkinson’s disease.

TOPOCUT’s design was led by the principles of universal design,

without compromising the user experience or creating a sense of differentiation.

TOPOCUT was chosen to be 1 of 4 objects that underwent advanced development,

including user testing and mass production adaptation.

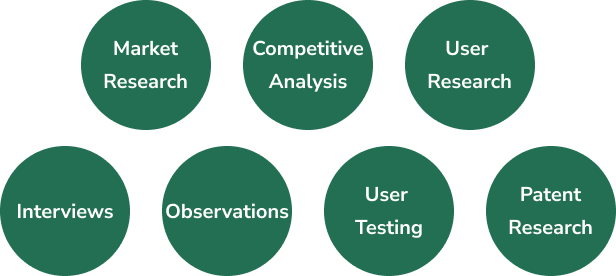

While working on TOPOCUT I used a number of research methods,

both in the area of design and medical research.

The research process accompanied the project throughout its developed stages

and touched on various issues according to the need that arose.

The first phase involved formulating a product idea.

After the medical research, a workshop and interviews with Parkinson’s patients.

This phase included also user research, market research, and similar product research.

Brainstorming

After the workshop

and meeting Parkinson’s patients

User research

Choosing leading concept

And market research

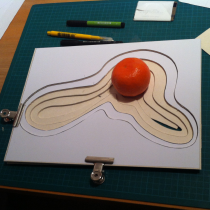

Mockups

Processing

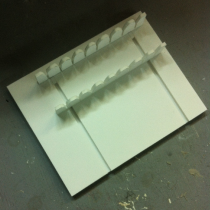

Model #1

The second phase deals with further development of TOPOCUT.

Accuracy of the user experiences, additional features, and changing materiality.

This phase included also observations, user testing, and patent research.

Processing

Conclusions of model #1

Mockups

User testing

Processing

Conclusions of user testing

Prototype

Going to mass production.

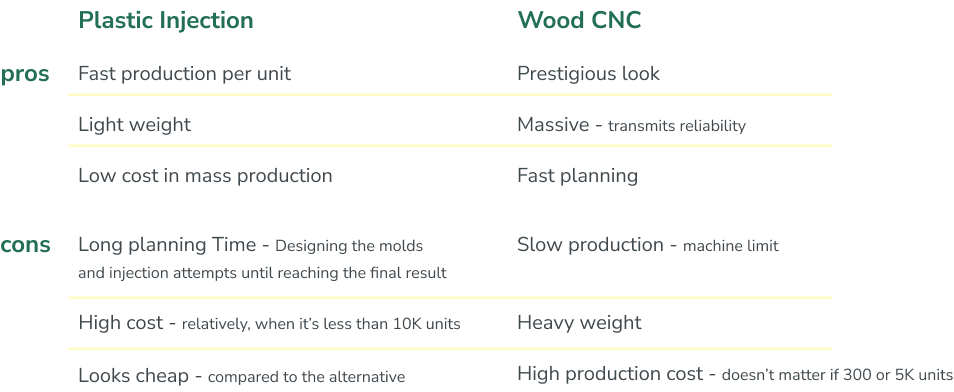

In this phase, I didn’t touch the design at all, only examined production methods

for the product as it is with minimum design intervention.

The various production methods affected directly the product visibility.

We focused on two main methods:

The chosen production method was wood CNC, when visibility is decisive.

We decided that the product should convey luxury, and reliability

something we could not achieve in plastic injection production.

Working on TOPOCUT took about two years.

I learned a lot from the process and it also gave me a glimpse of how

things work in the real world, outside the Bezalel incubator.

A world where production costs, compromises, and understanding of

organizational processes have heavy significance.

In the end TOPOCUT does not produce in mass production for several reasons:

High manufacturing costs versus the cost the pharmaceutical company

was interested in investing in.

Size – My product was the largest and most complex of the

four products were selected for further development.

My lack of compromise in favor of TOPOCUT production at any cost.

I am grateful for the learning process and glad by the opportunity to participate in it.

making decisions regarding the visibility and manufactured process,

even if the result was not mass-produced.